Cables, wires, and cords are exposed to various complex environmental stresses during their service life, including extreme temperatures, UV exposure, humidity variations, ozone corrosion, salt spray, and mechanical stretching. These factors can significantly affect their insulation performance, durability, and safety. Therefore, environmental simulation testing is essential before market deployment.

LIB Environmental Simulation Industry offers comprehensive testing solutions capable of simulating air aing, UV exposure, high-low temperature cycling, ozone aging, and corrosion, helping cable manufacturers evaluate product performance, ensure reliability, and comply with international standards.

420.9 sample air aging equipment should be as ASTM D 5423-93 (R1999) type oven (11) and ASTMD

5374-93 (R1999) described above, this device can make the air in the aging room high-speed circular flow., fresh air should be able to continue to enter the aging chamber to maintain the normal of oxygen content around the sample. Oven vent should adjust to ensure won 100-200 times per hour to complete the fresh air ventilation making cycle, such as fan, fan device should be completely in outdoor aging. Oven should maintain a specified temperature1.0°C (±1.8°F).

[Classify]

① Rate of Ventilation: 5~20 times/h (At a temperature of 100 ℃)

② Rate of Ventilation: 100~200 times/h (At a temperature of 100 ℃)

[Performance Requirements]

1. Rate of Ventilation: 5~20 times/h (①), 100~200 times/h (②)

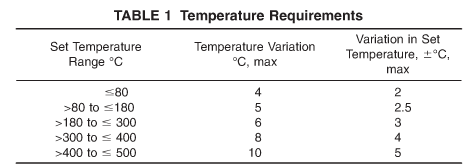

2. Set temperature, refer to table 1

3. Temperature variation, refer to table 1

4. Temperature fluctuation

5. Thermal lag time: the temperature delay cannot exceed 660s when working at 200℃.

[Structural Requirements]

1. The internal material should be anti-corrosion, anti-leakage, easy to clean.

2. There must be hinges and latches on the door to provide effective internal and external sealing, using gaskets.

3. When the actual oven temperature greatly exceeds the set value, the heating tube is automatically turned off.

4. There are ports for inhaling and exhausting air, and ducts for exhausting.

5. Damper for adjusting ventilation rate, air circulation.

For testing the smooth surface of the cable outer layer against UV

[Test Procedure]: one cycle/5 days

the first day: exposure to light, relative humidity≥85%RH, temperature 25±2 ℃ with spray (spray mineral water, each cycle lasts 3 minutes)

the second day: temperature 25±2 ℃ with high and low temperature thermal cycle, The hot and cold temperature conversion should be completed in the shortest time, and the cycle time of the two temperature shocks should be about 1-2 hours.

next 2 day: exposure to light, temperature 70±2 ℃, humidity <30%RH

the fifth day: exposure to 0.067% mol/L SO2 solution, temperature 40±3 ℃, the door can be opened 16 hours after the test

[Test piece preparation]

2 groups, 6 samples in each group, do the 5-day cycle test for one group; another one group are put in the environment, avoid the sun.

It's divided into outdoor use test and indoor use test according to usage.

Test plan A: test with xenon arc lamp

[Equipment apparatus]

1. Standard illumination 43W/m2 at 300~400nm,

2. Automatic control temperature, humidity, circulation,

3. Deionized water generator, the conductivity<5μS/cm,

4. Adjust the light intensity 43W/m2 at 300~400nm,

5. Other refer to ISO4892-2.

[Sample preparation]

Insulation holster detached from cable, at least 600mm long, 12 pieces

[Test Procedure]

1. Six samples were hung vertically, and evenly exposed to light during the test,

2. The black panel temperature should remain in the range of 60±3 ℃,

3. Humidity should remain in the range of 50±5%RH,

4. Rotation speed should turn at a speed of 1r/min,

5. The overall duration of the test shall be 720 h (360 cycles),

6. The periods of each cycle, total time of 120min, includes:

102 minutes of dry UV exposure at a temperature of 60±3 ℃, followed by 18 min of rain exposure, without radiation, at a temperature of is 50±5 ℃

After the exposure, the exposed test specimen shall be remove from the equipment and conditioned at ambient temperature for at least 16h. Another group of 6 sample shall be kept at ambient temperature and protected from direct sunlight during the UV treamentand tested at the same time as the exposed test specimens.

Test plan B: fluorescent UV lamp

There are different types of fluorescent UV lamps according EN ISO 4892-3;2006,5,1

①: UVA-340 lamp

②: UVB313 lamp

The specimens are positioned in a flat plane in front of an array of light sources according to ISO4892-1.

0.68W/m2 at 340nm for UVA 340 lamp

0.68W/m2 at 313nm for UVB 313 lamp

[Test Procedure]

600 minutes light, temperature 60±3 ℃,

120 minutes condensation exposure, no light, temperature 50±3 ℃,

Black panel temperature 60±3 ℃

The overall duration of the test is 720 mins, 60 cycles

After light exposure, the samples will be taken out and stay in the environment for at least 16 hours. Another group of 6 samples are kept at ambient temperature to avoid light exposure, and the corresponding procedures are also tested.

Control the irradiance to produce 43±0.2W/m2 at 340nm

Automatic temperature control and cycle test

[Test Procedure]

The six test samples were hung vertically, and evenly exposed to light.

the black panel temperature should remain in the range of 60±3℃ during the test.

The rotating speed of the turntable carrying the test piece is (1±0.1) r/min.

The overall duration of the test shall be 720 h (360 cycles).

The periods of each cycle, total time of 120min, including:

102 minutes of dry UV exposure at a black-standard temperature of 60±3 ℃, followed by 18 min of without radiation, at a black-standard temperature of 60±3 ℃.

After the exposure, the exposed test specimen shall be remove from the equipment and conditioned at ambient temperature for at least 16h.

The six other specimens shall be kept at ambient temperature and protected from direct sunlight during the UV treatment and tested at the same time as the exposed test specimens.

Use 5 complete samples,

The sample holder rotates at a speed of 1r/min,

There is at least 0.35W/m2 of the light division at 340nm wavelength,

Illumination for 2h, including 18 minutes of water spray, each cycle is 102 minutes of light and 18 minutes of light and water spray,

The PH value of the water spray device is 6.0~8.0, an 18:19 2020/6/1018:19 2020/6/10d the temperature is 16±5 ℃. The water used cannot be recycled If the water quality conditions are not met standard,

The black panel temperature is 63±3 ℃.

Type of test piece test results

The test shall be performed in preparing three batches of 6 pieces including one reference batch. Specimens similar to those specified for the tensile test are placed on supports allowing to apply to them in their middle part, a relative elongation of 20% (these supports are generally in vertical position).

- The reference batch shall be kept at the temperature under mechanical stress, avoiding direct sunlight, throughout the duration of testing.

- The first and the second batch shall be subjected to weathering effects during 3 weekly cycles.

- The first batch is then removed from the cabinet and conditioned alike the reference batch.

- The second batch shall be maintained in the cabinet and subjected to weathering effects during the last three weekly cycles.

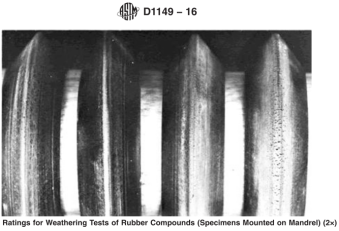

Test standard: ASTM D1149

Method A: Dynamic stretching

Method B: Static stretching

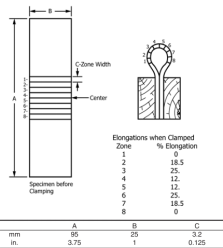

A1: Dynamic tensile elongation: The rectangular specimen has a dynamic maximum amplitude tensile strain of 25±3% at a fixed frequency of 0.5Hz (30cpm)

A2 Dynamic belt flex test: fix the rectangular test piece on the fabric belt, the fabric belt continuously rotates on two vertically opposed pulleys, and generates periodic surface strain (due to deflection) when passing the pulley

B1: Straight specimens (Static elongation) test: the rectangular test piece is continuously stretched to 20%

B2: Bent loop specimen test: rectangular sample, cyclic tensile

B3: Tapered specimen (static elongation) test: the sample is exposed to a set elongation and stretched (10%, 15%, 20%)

B4: Triangular specimens test: triangle sample, wound on a wooden mandrel, continuous tensile.

[Equipment apparatus]

1. The ozone concentration should in the range of 25~200pphm when ozone production at 100kpa, and the corresponding pressure value is maintained between 25 and 200mpa throughout the test.

2. The optional ozone concentration is 25, 50, 100, 200pphm and mpa.

[Sample preparation]

Rectangular strip, 10mm wide and 100mm long

[Test Procedure]

A1 test: dynamic stretching 0~25% stretching rate at 0.5Hz frequency (30cpm)

The standard ozone partial pressure is 50±5mpa (equivalent to 50pphm at 100kpa atmospheric pressure). Check the ozone partial pressure every day, especially when doing special tests.

A2 Test: 2 sets of pulleys, the first set pulley diameter is 63.5mm, the second set pulley diameter is 102mm, the first set pulleys drives the test piece to bend, with a frequency of 0.67Hz (40r/min). If use the second set pulley, the frequency is 1.04Hz, and the drive shaft rotates at 3.75Hz (225r/min).

[Sample preparation]

specimen 100*50*3mm

B1 Test: continuous stretching to 20%

Test piece: width 25mm, length 150mm, thickness 1.9mm

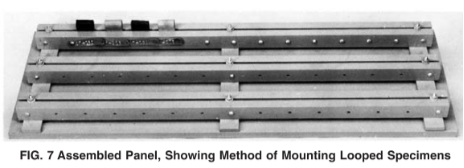

B2 Test: rectangular sample, cyclic stretching

Wrap the test piece on the wooden shaft or aluminum shaft, the two ends of the test piece are overlapped and fixed, and the distance between every two test pieces is at least 6mm.

B3 Static proportional tensile test: the sample is exposed to a set elongation of 10%, 15%, 20%.

B4: Static tensile triangle sample test: triangle sample, wound on a wooden mandrel, continuous tensile.

Standard ozone pressure values are: 25mpa, 50mpa, 100mpa and 200mpa.

Standard temperature is 40 degrees.

Method A: exposure series

[Test Procedure]

Sample under 40 + / - 1 ℃, ozone under pressure to 50 + 5 mpa exposed 72 h, unless to test both sides to negotiate each other test conditions. Samples should be in 46 h, 22 h, 70 h from the test chamber to observe crack series.

[Sample preparation]

Fix a chalk line on the sample, marking the middle distance 190 mm (7.5 inch), from the end of the 32 mm (1. 25 inches). The sample volume into ring shape, overlapping 19 mm (7. 5 inches) into the handle shape, at a chalk line to tie it with copper wire. Hang the sample on the mandrel until it is full

[Source of ozone gas]

A) Ultra-violet lamp

B) silent-discharge tube

Ozone airflow can be adjusted in the range of 12~16mm/s

[Sample preparation]

Wide test piece: 10mm in width, 2mm in thick, at least 40mm in length

Narrow test piece: 2mm in width, 2mm thickness, 50mm length, like

[Ozone Concentration]

250ppd ± 50ppd (25pphm ± 5pphm)

250ppd ± 50ppd (25pphm ± 5pphm)

1000ppd ± 100ppd (100pphm ± 10pphm)

2000ppd ± 200ppd (200pphm ± 20pphm)

Temperature: 40 ℃±2 ℃

Humidity: no more than 65%RH

Maximum stretch: (5±1)%,(10±1)%,(15±2)%,(20±2)%,(25±2)%,(30±2)%,(40±2)%,(50±2)%,(60±2)%,(80±2)%,

[Static Tensile Test Procedure]

Procedure A: Stretch 20%, check the sample after 72h.

Procedure B: Stretch 20%, check samples after 2h, 4h, 8h, 24h, 48h, 72h and 96h.

Procedure C: Check the sample after 2h, 4h, 8h, 24h, 48h, 72h and 96h,stretching for no less than 4 times.

[Dynamic Tensile Test]

Procedure A: at 0~10% stretch rate, 0.5Hz frequency, check the sample after 72h.

Procedure B: checking the sample after 2h, 4h 8h, 24h, 48h, 72h and 96h, Proportional stretching from 0 to above, 0.5Hz.

Warning: The oxygen concentration in the workroom should not exceed 0.1 x 10-6(ozone per million volumes of air).

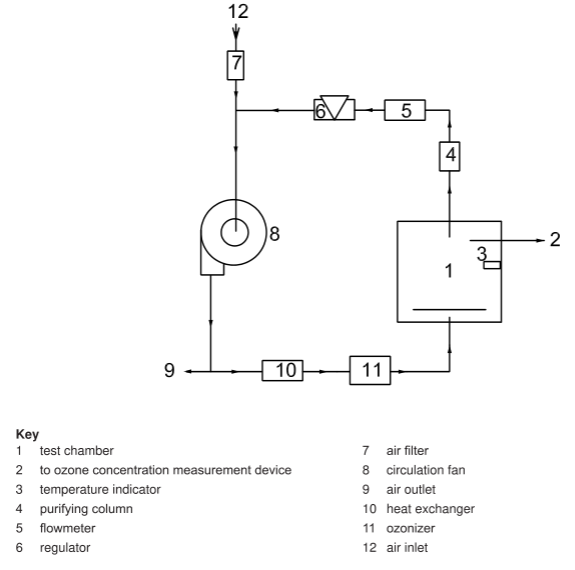

[Test equipment]

A) Ozone-generating devices capable of controlling the amount of ozone;

B) Under controlled humidity and temperature conditions, ozone passes through the circulation system with the test chamber;

C) A device for determining the percentage of ozone concentration;

D) Clamping fixture of specimen and tensile specimen;

E) Cylindrical wooden bar or metal bar;

D) A dryer fitted with silica gel or its equivalent;

G) Balances with precision of 0.1 mg.

[Insulation Sample preparation]

No matter single core or multicore cable is, need to choose one insulated wire core experiment, from the end is not less than 1.5 m take key, the length of the insulation wire core, in the preparation of 2 samples; Such as wire core outside extruded semi-conducting layer, the preparation of 4 samples should be cut out enough insulation wire core, all test specimens shall be no visible mechanical damage.

All outer sheathing shall be removed from the insulation core without damaging the insulation, unless the sheathing is directly coated on the insulation and adhered to the insulation before vulcanization.

If there is a wrapped semiconductive layer outside the insulation core, it should be removed.

If there is an extruded semi-conductive shielding layer outside the insulation core, the semi-conductive shielding layer of two samples should be removed and the other two samples retained

[Sheathed sample preparation]

Should take enough length of cable or wire samples, or from the cable samples on the rest of the sheath, with at least two specimen preparation.

The minimum thickness of specimen is 0.6 mm.

For the preparation of dumbbell specimen cannot small size cable sample, is carried out in accordance with the insulation test method of sample.

[Sample pretreatment and bending]

Insulation sample:

If there is no extruded insulation wire core semiconduction shielding layer, a sample shall be along its original bending direction and plane without twisting around.

A full circle on the test bar, and in the end intersections with a rope or strap fastened; The second sample should be the same along its original bending plane bending, but in the opposite direction.

Such as insulation wire core with extruded semiconduction shielding layer, you should keep the removal of semi-conducting layer sample and semi-conducting layer of sample as mentioned above, respectively bend in both directions.

Should be at room temperature or take the bend specimens under high temperature 20 ℃, should adopt Huang Li, aluminum or properly deal with wooden test bar, its diameter should be stipulated in the table 1:

Insulation wire core diameter d/mm | Test bar diameter (multiples) insulation wire core diameter |

d≤12.5 | 4±0.1 |

12.5<d≤20 | 5±0.1 |

20<d≤30 | 6±0.1 |

30<d≤45 | 8±0.1 |

45<d | 10±0.1 |

If the sample is too hard so that the two end cross, the sample should be in the regulation of the diameter of the test bar bending at least 180 "and fastened.

The surface of every sample application a clean piece of cloth wipe away dirt or moisture, before the test, the test on a curved sample shall be placed in the air at ambient temperature (30 ~ 45 min), without the need for further processing.

Sheathed specimens:

Each surface of the specimens are used a clean piece of cloth wipe away dirt or moisture, samples should be stored in 23℃ to + / - 5℃ of dryer Less 16 h. The ends of the specimen clamp fixture for, make specimen elongation of 33% plus or minus 2% on the jig. Note, in order to avoid specimen cracking near the jig, can under the fixture of specimen coated with ozone resistant paint.

[Test Procedure]

The treated specimens shall be placed in a test chamber with a cock in central; The distance between the two specimens for at least 20 mm.

The sample should be kept in (25 + 2)℃ temperatures, and exposed to a regulation of ozone concentration in the air drying cycle.

The ozone concentration and duration according to the regulations on cable product standards.

With a specified concentration ozone in the air, and its flow should be controlled in 280 L/h and 560 L/h, between the air pressure should be kept in the cabinet slightly above atmospheric pressure.

The brine concentration is 5% NACL

Gas environment Test Method 1:

Under saturated humidity, the SO2 concentration is 0.0667% (667 parts per million by volume).

Cycle testing 7 days a week.

24 hours 7 days (168 hours in total), each cycle contains 8 hours of high humidity exposure, and high SO2 concentration exposure, and 16 hours of ambient room temperature exposure.

Test Method 2:

Compound salt spray test, containing 1 hour dry, 1 hour spray, 500 inquiries (total 1000 hours).

Spray at room temperature and dry at high temperature.

Settlement 1~2ml/80cm2/h.